|

Terry Lippincott has rebuilt dozens and

dozens of XK engines over the past 35 years,

including his own race-prepped engines.

This experience has been developed into

a well-defined rebuild procedure, one that

he shares with his trusted machine shop.

This experience has also taught him which

upgrades work and those that don't.

For example, the XK head responds very

well to porting and polishing. Done properly,

reshaping the port walls can improve the

quality and quantity of the air flow into

the combustion chamber resulting in a significant

increase in engine power output. With years

of practice, backed by air flow bench testing,

Terry knows how to port and polish the XK

head to maximize breathing.

|

|

| Machined

block, surfaced, bored and painted. |

|

|

Terry also routinely uses modern, higher

compression pistons to achieve additional

horsepower while still requiring only premium

octane pump-grade fuel.

Many engines also receive slightly-hotter-than-stock

Isky racing cams.

These piston and cam upgrades along with

the head work described above and proper

carburetor

settings combine to create a noticeable

increase in torque and horsepower without

altering the streetablilty of the engine.

|

|

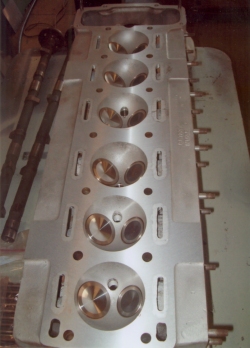

| These

are modern, high compression pistons

that work nicely with the XK engine's

hemi combustion chamber. |

|

|

| Crankshaft

fresh from the machine shop. |

|

|

| A

newly machined engine block with crank

installed. |

|

|

|

|

|

| Pistons,

bearings and oil pump installed. |

|

|

|

| Installing

the lower timing chain and tensioner. |

|

|

|

| A

new, improved style of tensioner is

being used here. |

|

|

|

| Timing

chain cover and water pump are installed.

Next we're cleaning up the head bolt

hole threads by running a tap down the

holes. |

|

|

|

| High

compression pistons and head studs installed. |

|

|

|

| Using

a hoist to lower the head into position

over the head bolt studs. |

|

|

|

| Head

installed. Note use of tappet guide

hold down kit. This customer requested

that the kit be installed on both the

intake and exhaust cam. |

|

|

|

| Almost

completely buttoned up. |

|

|

|

| Intake

side of the almost-completed engine

assembly. |

|

|

|

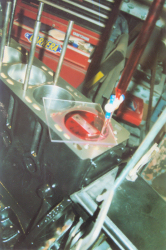

| CC'ing

the area above the piston to the top

of the block. Careful measurements assure

that we get the correct compression

ratio. |

|

|

| For

those interested in originality, a set

of domed, OEM-style pistons ready for

installation. |

|

|

|

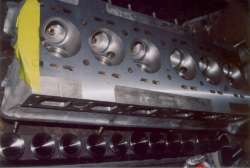

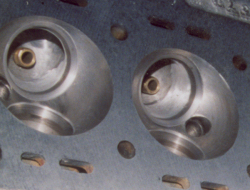

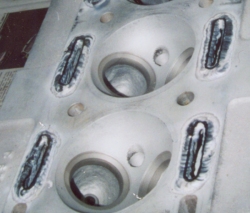

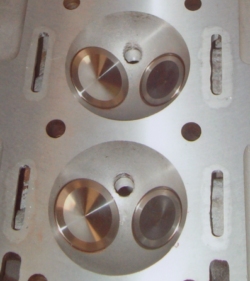

| The

photos above show a 1968 E-Type head

with larger valve seats installed,

ready to accept the later-style, 1

7/8-inch "big valves". You

can also see where the ports have

been cleaned up. This setup is very

well optimized for maximum air flow. |

|

|

Cylinder

Head Corrosion Repair Cylinder

Head Corrosion Repair |

|

|

It's not unusual for the aluminum XK heads

to suffer from severe corrosion due to the

lack of proper coolant maintenance. Serious

cases will find the water jacket openings

near the block surface literally eaten away

from years of neglect.

Many of these heads can be

sucessfully repaired by the careful and

skillful welding-in of new material to replace

the decayed aluminum, followed by surface

machining.

|

|

|

|

|

| The

water jacket openings on this head

have been built-up to repair a case

of severe corrosion. |

|

|

| The

repaired head is machined smooth. The

new valves are also installed. |

|

| |

|

| This

is a closeup view of the repairs. Next,

the head surface is machined. |

|

|

| Closeup

view of repaired water jacket openings. |

|

| |

|

| Repaired

and machined head. |

|

|

| |

|